In the fast-evolving world of maker tools, the Mr Carve M7 Pro has just landed on Kickstarter with a bold promise: to completely change how we think about engraving and personalisation. It’s not just another desktop laser; it’s billed as the world’s first 3D-Inner-Flat Engraver powered by a triple-function 5 W UV cold laser that can etch intricate details on virtually anything you can imagine, from crystal to leather to metal, without burning or damaging the surface.

This machine is positioned at the sweet spot between industrial capability and home-studio convenience—something that will appeal to both professional creators and hobbyist tinkerers. But is it just Kickstarter hype, or does the M7 Pro genuinely bring something new to the table? Let’s take a deep dive.

The Big Idea: Three Engraving Modes, One Machine

Most desktop laser engravers do one thing reasonably well—engraving on flat surfaces—or, in some premium cases, light 3D relief work. The Mr Carve M7 Pro throws that single-purpose limitation out of the window.

It offers three distinct engraving modes:

-

3D Relief Engraving – Perfect for creating textured depth on wood, acrylic, leather, and metal. Think high-end signage, custom panels, or art pieces that you can run your fingers over.

-

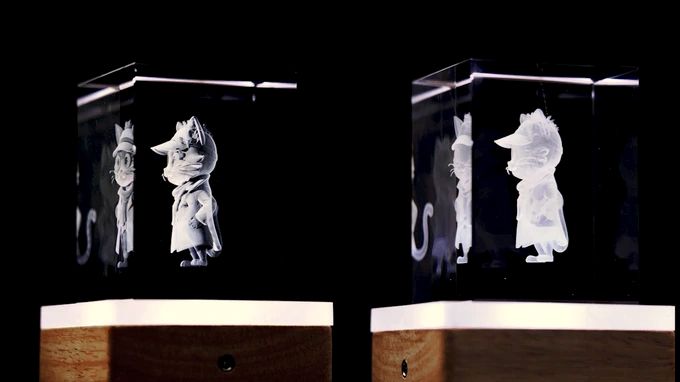

Inner Engraving – Using a special UV laser wavelength, the M7 Pro can engrave inside transparent materials such as crystal and acrylic—without damaging the outer surface. This is the kind of process usually reserved for expensive commercial crystal gift manufacturing.

-

Flat Surface Engraving – The bread-and-butter function, but with a twist—its ultra-precise beam allows detailed logos, photos, and patterns without burn marks, even on sensitive materials.

This 3-in-1 approach is a rare find in the consumer market. Instead of buying multiple machines—or outsourcing certain jobs—you get an all-in-one platform that can handle a much broader range of projects.

Laser Power and Precision: What 5 W UV Really Means

If you’ve worked with lasers before, you might be used to seeing wattages like 10 W, 20 W, or even 40 W on CO₂ and diode machines. So why does the M7 Pro “only” have 5 W?

Because power isn’t the whole story—especially when we’re talking about a UV cold laser.

Here’s why that matters:

-

Wavelength advantage – At 355 nm, UV lasers are absorbed more efficiently by a wider range of materials, including plastics, glass, and metals that diode and CO₂ lasers struggle with.

-

Zero-burn promise – Unlike infrared or CO₂ lasers that can scorch or melt surfaces, UV lasers produce far less heat. That means clean, sharp edges with no charring—a huge plus for premium products.

-

Higher precision – The M7 Pro boasts ±0.001 mm accuracy, enabling the engraving of excellent text or microscopic patterns that remain crisp under magnification.

In short, while a CO₂ machine might power through a 10 mm wood board, the M7 Pro is about finesse, detail, and the ability to work on sensitive or otherwise “impossible” surfaces.

Speed to Match the Accuracy

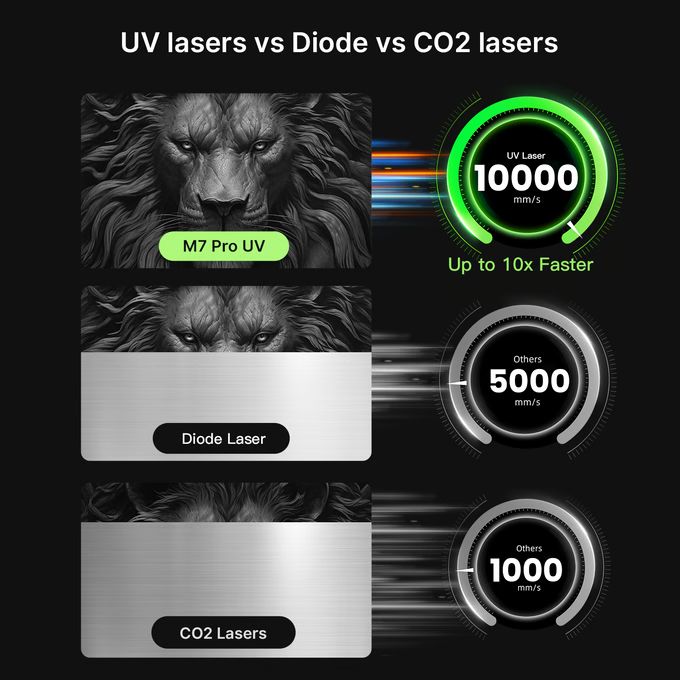

A common trade-off with high-precision engraving is speed—meticulous detail usually takes longer. The M7 Pro claims to solve this problem by engraving at speeds up to 10,000 mm/s.

This is made possible by:

-

Galvanometer scanning heads for lightning-fast beam positioning.

-

Helios 3D Smart Recognition AI for automatic object detection and optimal laser path planning.

-

Motorised Z-axis that can adjust focus without manual tinkering, keeping jobs efficient.

For small business owners, speed is more than convenience—it’s directly tied to profit. If you can engrave a batch of 50 custom tumblers in half the time, your turnaround (and income) potential increases significantly.

Real-World Applications: From Hobbyists to High-End Manufacturing

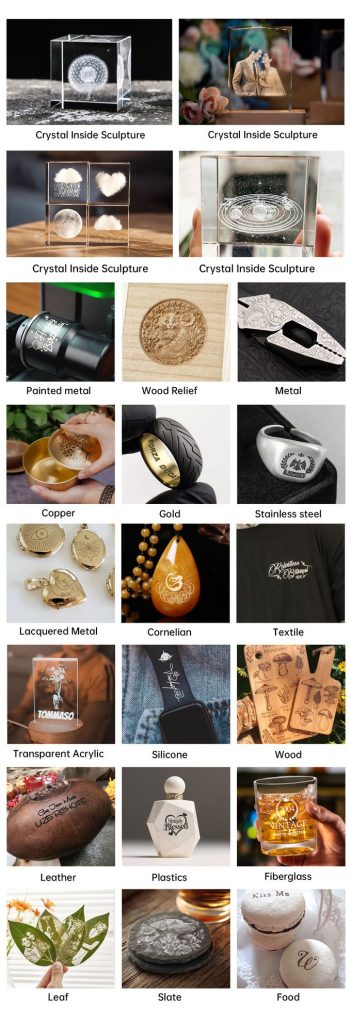

Where the M7 Pro stands out is in its material compatibility. According to the Kickstarter campaign, it can engrave on over 1,500 types of materials.

Here are a few real-world scenarios:

-

Crystal Awards & Gifts – 3D inner engraving of corporate logos or personalised messages without surface scratches.

-

Custom Electronics – Marking serial numbers, circuit boards, or cases without melting components.

-

Luxury Leather Goods – Personalising handbags, belts, or wallets without burn marks that ruin the finish.

-

Jewellery & Watches – Adding micro-detail engraving on metal surfaces for branding or decoration.

-

DIY Crafts & Etsy Shops – Creating unique keychains, ornaments, and small-batch art pieces.

-

Industrial Parts Marking – Permanent, high-contrast markings on metal tools and components.

The beauty is that a single machine can cross over between artistic creation and industrial-grade marking—something few desktop engravers can do.

Rotary Attachment: 360° Creativity

Flat work is fine, but cylindrical and spherical objects open up a whole new creative dimension. The M7 Pro comes with an optional rotary axis that allows for:

-

Full wrap-around designs on mugs, bottles, and pens.

-

Engraving on spherical objects like ornaments.

-

Perfect alignment for multi-pass jobs on rounded surfaces.

This makes it an attractive option for custom drinkware businesses or artists who like working with more complex geometries.

Safety and Build Quality

Laser engravers can be intimidating—after all, you’re working with concentrated beams of light powerful enough to vaporise materials. The M7 Pro addresses safety with:

-

FDA Class 1 fully enclosed design – No exposed laser light during operation.

-

Smoke-free operation – Built-in exhaust and filtration.

-

All-metal frame – Ensuring stability and durability.

It’s not just about compliance—it also means you can run it safely in a home studio or small office without elaborate safety setups.

Software and Workflow

The M7 Pro ships with MRCARVE Laser Suite, which works on both Windows and macOS and supports a wide range of file formats:

-

Raster images – JPEG, PNG, BMP

-

Vector files – AI, DXF, SVG

-

3D models – STL, OBJ

This compatibility is crucial because it allows users to work in their favourite design software (Illustrator, CorelDRAW, Fusion 360, etc.) and easily import into the engraver’s interface.

The AI-assisted workflow reduces the learning curve—helpful for newcomers who might otherwise be intimidated by the complexity of laser operation.

Video Credit – SamiLuoTech

Technical Specifications at a Glance

| Feature | Detail |

|---|---|

| Laser Type | 355 nm UV DPSS |

| Laser Power | 5 W CW |

| Precision | ±0.001 mm |

| Speed | Up to 10,000 mm/s |

| Engraving Area | 50×50 mm or 150×150 mm (interchangeable lenses) |

| Cooling | Active air cooling |

| Weight | ~22 kg |

| Dimensions | 272 × 533 × 539 mm |

| Material Compatibility | Over 1,500 types |

| Software | MRCARVE Laser Suite |

| OS Support | Windows & macOS |

Kickstarter Campaign Details

The Kickstarter for the M7 Pro launched today, 14th August, with a clear set of incentives:

-

$10 reservation pledge – Secures your spot in line.

-

Early bird deal – Up to $900 off the final retail price.

-

Free Creator Starter Kit worth $439 for early backers.

-

Pledge Over Time option – Interest-free instalments over three months.

Given that crowdfunding campaigns often sell out of early bird tiers quickly, those interested will want to move fast.

How It Stacks Against Competitors

Let’s briefly compare the M7 Pro with common market alternatives:

-

Diode lasers – Affordable but often limited in material compatibility and prone to burning delicate surfaces.

-

CO₂ lasers – Powerful for cutting but less precise on fine detail, and often require bulky setups with water cooling.

-

Fibre lasers – Great for metal marking, but usually single-purpose and very expensive.

The M7 Pro carves (pun intended) a niche by combining precision, material versatility, and three engraving modes in a single enclosed unit, without needing industrial-scale space or budget.

Who Should Buy It?

The M7 Pro is not just for laser engraving veterans. Here’s who might benefit most:

-

Creative Entrepreneurs – Etsy sellers, small gift shops, and print-on-demand businesses looking to expand product lines.

-

Professional Designers – Architects, jewellery designers, and product developers who need rapid, precise prototyping.

-

Educational Makerspaces – Schools or universities with design or engineering programs.

-

Industrial Users – Small manufacturing businesses needing permanent, precise part marking.

If you value detail over raw cutting power, and you work with a variety of materials, the M7 Pro is a serious contender.