At CES 2026, AtomForm officially unveiled the Palette 300, a next-generation desktop 3D printer that represents a significant leap forward for both consumer and professional fabrication. Designed to eliminate the long-standing compromises of multi-colour and multi-material printing, the Palette 300 transforms complex digital ideas into vivid, physical reality—faster, cleaner, and with unprecedented precision.

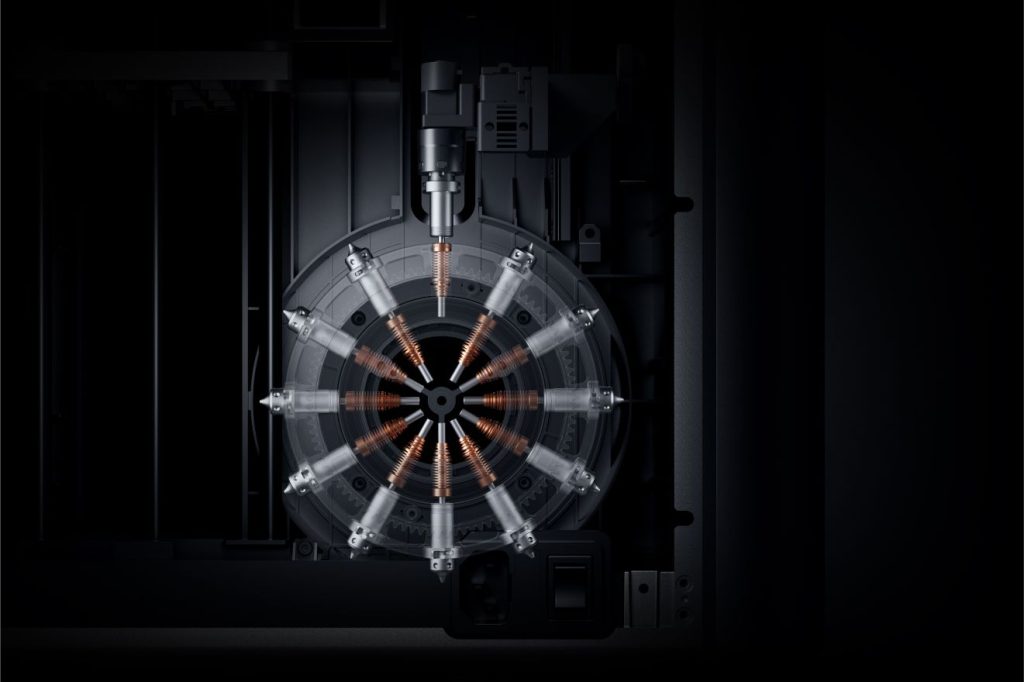

Built around a sophisticated 12-nozzle architecture, the Palette 300 introduces advanced multi-material printing with lightning-fast nozzle swaps, reducing filament waste by up to 90%. The result is a system that redefines expectations for desktop fabrication, offering speed, accuracy, and creative freedom without the usual trade-offs.

As part of the MOVA Group, AtomForm will be showcasing the Palette 300 throughout CES 2026 at the MOVA Booth (LVCC, North Hall — 10315).

Twelve Nozzles, Virtually Unlimited Creative Freedom

Most desktop 3D printers restrict creators to one or two colours at a time. The Palette 300 removes that limitation entirely. With 12 dedicated, filament-specific nozzles, users can combine up to 36 colours and 12 different materials within a single print.

This opens the door to an entirely new class of creations—from models that seamlessly blend rigid and flexible components, to realistic finishes that require no post-processing, painting, or manual assembly. Whether you’re a designer, engineer, educator, or hobbyist, the Palette 300 enables prints that are as expressive and detailed as the ideas behind them.

At the core of the system is AtomForm’s breakthrough OmniElement Automatic Nozzle Swapping System. Unlike conventional multi-head or single-nozzle colour-mixing solutions, OmniElement optimises colour and material transitions with exceptional efficiency. It maintains ±0.02mm precision, dramatically shortens swap times, and keeps filament waste to an absolute minimum—all while ensuring consistent surface quality throughout long, complex prints.

Faster Printing, Less Waste, Better Results

Multi-material printing has traditionally meant slow workflows and excessive purging. The Palette 300 changes that equation entirely. Thanks to ReadyPrint swap technology and independent nozzle management, filament transitions happen quickly and cleanly, allowing prints to continue smoothly without interruption.

With a maximum print speed of 800 mm/s and 25,000 mm/s² acceleration, the Palette 300 delivers industrial-grade performance in a desktop-friendly form factor. Complex, multi-colour models that once took days can now be completed in a fraction of the time—without sacrificing accuracy or reliability.

AI-Driven Precision You Can Trust

Behind the scenes, the Palette 300 operates with an impressive level of intelligence. The system is equipped with more than 50 smart sensors and four AI-powered cameras, continuously monitoring every aspect of the print process.

From automatic nozzle alignment and real-time calibration to early defect detection, the printer acts like a silent assistant—correcting issues before they compromise a print. This intelligent oversight significantly improves first-time success rates while maintaining ±0.02mm dimensional accuracy, giving creators confidence that even the most ambitious projects will print the first time.

Built for Studios, Schools, and Shared Workspaces

Despite its advanced capabilities, the Palette 300 is engineered for everyday creative environments. Ultra-quiet operation rated at ≤48 dB, combined with integrated air filtration, makes it well-suited for home studios, classrooms, offices, and shared maker spaces.

For users working at scale, the system integrates seamlessly with up to six AtomForm RFD-6 Filament Boxes, supporting a total of 36 spools. Each filament box features independent, continuous drying technology that operates even while printing, ensuring optimal material performance across long jobs and mixed-material builds. Together, they form a robust and reliable ecosystem for advanced multi-material production.

Key Specifications and Highlights

-

12 Auto-Swapping Nozzles

Independent, filament-dedicated nozzles eliminate reloading and purging, improving stability and surface quality. -

Up to 36 Colours & 12 Materials in a Single Print

Unmatched flexibility for personalisation, prototyping, and artistic creation. -

OmniElement & ReadyPrint Swap Technology

Reduces filament waste by up to 90% while delivering fast, seamless transitions. -

800 mm/s Print Speed & 25,000 mm/s² Acceleration

Industrial-tier performance in a consumer-ready system. -

300 × 300 × 300 mm Build Volume

Ideal for large projects, multi-part assemblies, and batch production. -

50 Sensors & 4 AI Cameras

Intelligent monitoring that dramatically increases first-print success rates. -

≤48 dB Quiet Operation with Air Filtration

Designed for safe, comfortable use in homes, schools, and offices.

AtomForm’s Vision for the Future of 3D Printing

“The Palette 300 isn’t about incremental improvement—it’s about removing the long-standing barriers of multi-colour, multi-material 3D printing,” said Jagger Shang, Head of Product at AtomForm. “We built a platform where creators don’t have to choose between detail, colour, material diversity, or speed. With 12 nozzles, intelligent filament management, and AI precision, they can finally have it all.”

Shang added, “Whether you’re producing full-colour gifts, classroom models, functional prototypes, or intricate artistic pieces, the Palette 300 puts professional-grade creation directly into people’s hands. This is about unlocking creativity at lightning speed—without compromise.”

Availability and Pricing

The AtomForm Palette 300 is scheduled for commercial release in early Q2 2026, with a retail price of $2,199. Early adopters will be able to take advantage of special launch discounts through a Kickstarter pre-order campaign beginning in early Q1 2026.